Thang cáp điện được sử dụng phổ biến tại những dự án điện, điện nhẹ với nhiều chức năng quan trọng. Những năm gần đây, ngành xây dựng đang ngày càng phát triển nên chúng đang được nhiều khách hàng quan tâm lựa chọn. Hãy cùng Nhà Máy Cơ Khí P69 tìm hiểu kỹ càng về sản phẩm này thông qua bài viết dưới đây nhé.

1. Thang cáp điện là gì?

Thang cáp điện có tên tiếng anh là “Ladder Tray”, là một thành phần không thể thiếu trong ngành công nghiệp cơ điện và xây dựng. Thiết kế đặc biệt của thang cáp cho phép nó hoàn thành một loạt các nhiệm vụ quan trọng trong việc quản lý và bảo vệ các dây cáp điện, cáp mạng và dây dẫn khác trong nhiều môi trường khác nhau.

Sản phẩm có chức năng hỗ trợ tạo ra hệ thống cáp điện một cách có tổ chức và quản lý hiệu quả, tránh việc bị rối, vướng vào nhau hoặc bị hỏng cũng như đảm bảo cáp điện không tiếp xúc với mặt đất hoặc các yếu tố gây nguy hiểm khác.

Bên cạnh đó, hệ thống thang cáp dễ dàng mở rộng và điều chỉnh, cho phép bạn linh hoạt thay đổi trong hệ thống thang máng cáp của bạn theo thời gian, góp phần tối ưu thời gian và công sức cần thiết cho việc bảo trì và nâng cấp hệ thống điện.

2. Ứng dụng của thang cáp điện

Trong ngành công nghiệp, các nhà máy sản xuất và nhà máy điện thường sử dụng thang cáp để quản lý và bảo vệ hàng ngàn mét cáp điện, cáp mạng và dây dẫn. Sản phẩm giúp tạo ra một hệ thống dây cáp sạch sẽ, dễ quản lý và an toàn trong các môi trường công nghiệp phức tạp và có điều kiện khắc nghiệt.

Tương tự, thang cáp điện cũng được sử dụng trong các trung tâm dữ liệu, hệ thống máy tính, các công trình thương mại để sắp xếp, quản lý và bảo vệ cáp mạng một cách có tổ chức, đảm bảo hiệu suất, sự tin cậy của hệ thống mạng cũng như duy trì không gian sinh hoạt gọn gàng và an toàn cho mọi người.

Thang cáp cũng được sử dụng trong các ứng dụng an toàn, bao gồm hệ thống báo động, chữa cháy và an ninh. Chúng giúp che khuất và bảo vệ các cáp liên quan đến các hệ thống an toàn và an ninh.

3. Ưu điểm của thang cáp điện

Sự an toàn của hệ thống điện luôn là mối quan tâm hàng đầu khi thi công bất cứ một công trình điện nào, chính vì vậy mà thang cáp điện trở nên phổ biến hơn khi ưu điểm của chúng là đảm bảo an toàn cho hệ thống điện. Khi được lắp đặt đúng cách và tuân theo các chuẩn kỹ thuật, chúng giúp ngăn chặn tiếp xúc ngẫu nhiên với dây cáp, giảm nguy cơ sự cố điện và bảo vệ nhân viên và tài sản.

Ngoài ra, triển khai hệ thống thang cáp điện sẽ giúp bạn tận dụng tối đa diện tích đi cáp trong các công trình điện hơn so với việc áp dụng các đường ống truyền cáp truyền thống. Đặc biệt, đây là lựa chọn tối ưu cho các công trình có mật độ dây cáp dày đặc bởi thiết kế gọn gàng và không chiếm nhiều diện tích.

Hơn nữa, tiết kiệm chi phí thi công lắp đặt cũng là điểm nhấn của sản phẩm. Chúng giúp giảm từ 20% đến 55% chi phí lao động và nguyên vật liệu. Tỷ lệ chi phí tiết kiệm cụ thể có thể thay đổi tùy theo kích thước và quy mô của hệ thống điện. Tuy nhiên, để tận dụng tối đa sự tiết kiệm chi phí, bạn cũng cần xác định sự cần thiết và tính toán tổng chi phí được thực hiện ngay từ giai đoạn thiết kế dự án.

Ngoài các ưu điểm trên, thang cáp điện còn được đánh giá cao vì có độ bền vượt trội, nhờ sử dụng chất liệu thang mạ kẽm, sơn tĩnh điện giúp đảm bảo độ bền đẹp với thời gian cùng với khả năng chống oxy hóa hiệu quả, cực phù hợp với điều kiện thời tiết nóng ẩm của nước ta.

4. Cấu tạo thang cáp điện

Thang cáp điện có cấu tạo vô cùng đơn giản với thành thang và tay thang. Thành thang giúp định hình và chịu tải trọng của các dây cáp điện và được liên kết bởi các tay thang. Số lượng và kích thước của tay thang có thể thay đổi tùy thuộc vào kích thước của sản phẩm cũng như yêu cầu cụ thể của khách hàng.

Thang cáp điện thường được sản xuất với chiều dài tiêu chuẩn khoảng 2,5m đến 3m cho mỗi cây. Sản phẩm có độ dày vật liệu thường từ 1,5mm đến 2mm và có thể tùy biến theo yêu cầu cụ thể. Ngoài ra, chúng còn có thể đi kèm với các phụ kiện như cút nối thẳng, nối T, chữ thập, hoặc co lên xuống.

5. Bảng kích thước tiêu chuẩn của thang cáp

Bảng kích thước tiêu chuẩn của thang cáp là một yếu tố quan trọng trong thiết kế và triển khai các hệ thống điện và dây cáp. Việc lựa chọn kích thước phù hợp có thể ảnh hưởng đáng kể đến hiệu suất và hiệu quả của hệ thống. Sản phẩm thường có nhiều kích thước, cung cấp sự đa dạng cho từng công trình với từng yêu cầu và mục tiêu cụ thể của dự án. Dưới đây là bảng kích thước tiêu chuẩn của Nhà Máy Cơ Khí P69!

| Kích thước Đơn vị (mm) | Độ dày tôn (Đơn vị mm) | ||

| 1.0 | 1.2 | 1.5 | |

| 50×50 | 50.000 | 55.000 | 60.000 |

| 60×40 | 55.000 | 60.000 | 65.000 |

| 75×50 | 60.000 | 65.000 | 70.000 |

| 100×50 | 65.000 | 70.000 | 75.000 |

| 100×75 | 70.000 | 75.000 | 80.000 |

| 100×100 | 75.000 | 80.000 | 85.000 |

| 150×50 | 80.000 | 85.000 | 90.000 |

| 150×75 | 85.000 | 90.000 | 95.000 |

| 150×100 | 90.000 | 95.000 | 100.000 |

| 200×50 | 95.000 | 100.000 | 105.000 |

| 200×75 | 100.000 | 105.000 | 110.000 |

| 200×100 | 105.000 | 110.000 | 115.000 |

| 250×50 | 110.000 | 115.000 | 120.000 |

| 250×100 | 115.000 | 120.000 | 125.000 |

| 300×50 | 120.000 | 125.000 | 130.000 |

| 300×75 | 125.000 | 130.000 | 135.000 |

| 300×100 | 130.000 | 135.000 | 140.000 |

| 350×50 | 135.000 | 140.000 | 145.000 |

| 350×75 | 140.000 | 145.000 | 150.000 |

| 350×100 | 145.000 | 150.000 | 155.000 |

| 400×50 | 150.000 | 155.000 | 160.000 |

| 400×100 | 155.000 | 160.000 | 165.000 |

| 400×150 | 160.000 | 165.000 | 170.000 |

| 500×50 | 165.000 | 170.000 | 175.000 |

| 500×100 | 170.000 | 175.000 | 180.000 |

| 500×150 | 175.000 | 180.000 | 185.000 |

| 600×100 | 180.000 | 185.000 | 190.000 |

| 600×150 | 185.000 | 190.000 | 195.000 |

| 600×200 | 190.000 | 195.000 | 200.000 |

| 800×100 | 195.000 | 200.000 | 205.000 |

| 800×150 | 200.000 | 205.000 | 210.000 |

| 800×200 | 205.000 | 210.000 | 215.000 |

| 1000×100 | 210.000 | 215.000 | 220.000 |

| 1000×150 | 215.000 | 220.000 | 225.000 |

| 1000×200 | 220.000 | 225.000 | 230.000 |

6. Các loại thang cáp phổ biến

6.1 Thang cáp sơn tĩnh điện

Thang cáp sơn tĩnh điện được làm từ các tấm thép carbon hoặc hợp kim thép được phủ một lớp sơn tĩnh điện để bảo vệ bề mặt và tạo một lớp màng cách điện cho sản phẩm.

Đặc tính chính của thang cáp sơn tĩnh điện là khả năng chống ăn mòn, giúp bảo vệ bề mặt của sản phẩm khỏi tác động của môi trường ẩm ướt. Điểm đặc biệt của loại thang này là khả năng cách điện, giúp đảm bảo an toàn trong việc treo, quản lý dây cáp, ống dẫn cáp và cáp mạng.

6.2 Thang cáp mạ kẽm nhúng nóng

Thang cáp mạ kẽm nhúng nóng là sản phẩm có bề mặt kim loại được đưa vào bể mạ kẽm ở nhiệt nóng cháy. Việc này sẽ tạo ra một lớp bề mặt kẽm có độ bền cao và có khả năng chịu mài mòn và oxy hóa tốt. Loại thang này được sử dụng trong những công trình có môi trường khắc nghiệt.

Tuy nhiên, sản phẩm có giá thành đắt hơn so với các loại thang cùng loại bởi chi phí sản xuất và đầu vào cao. Khách hàng nên lên dự toán và thiết kế chi tiết để sử dụng loại thang này một cách hợp lý nhất.

7. Các loại phụ kiện thang cáp

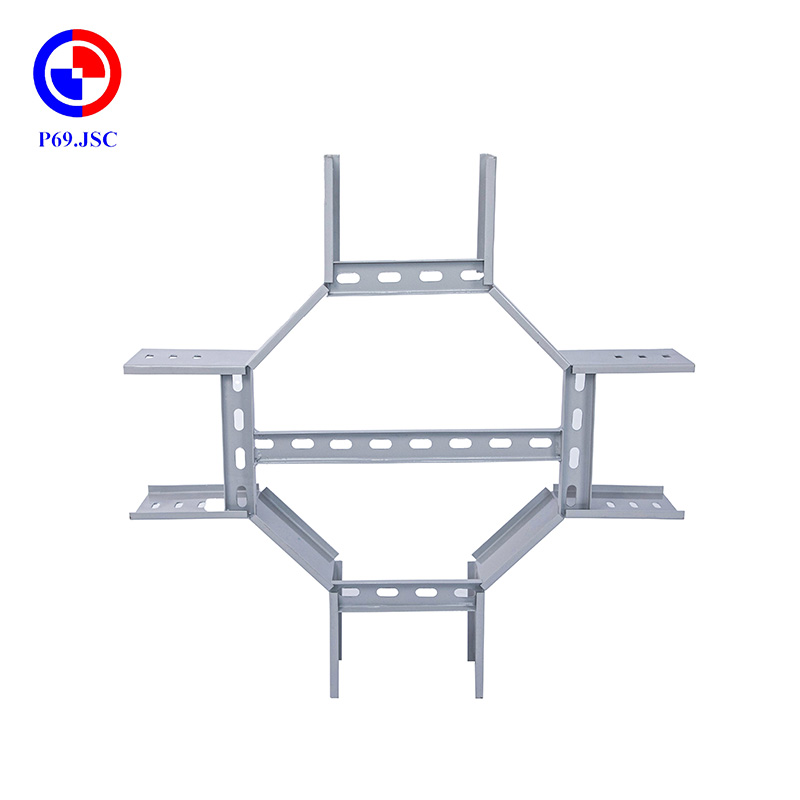

7.1 Chữ thập

Phụ kiện chữ thập là một phần quan trọng trong hệ thống thang cáp, chúng có khả năng chia hệ thống thành 4 phần riêng biệt mà vẫn duy trì trên cùng một mặt phẳng ban đầu. Điều này giúp tạo ra sự linh hoạt cho việc xây dựng và sắp xếp hệ thống thang cũng như cho phép tạo ra các ngã khác nhau để tăng tính linh hoạt.

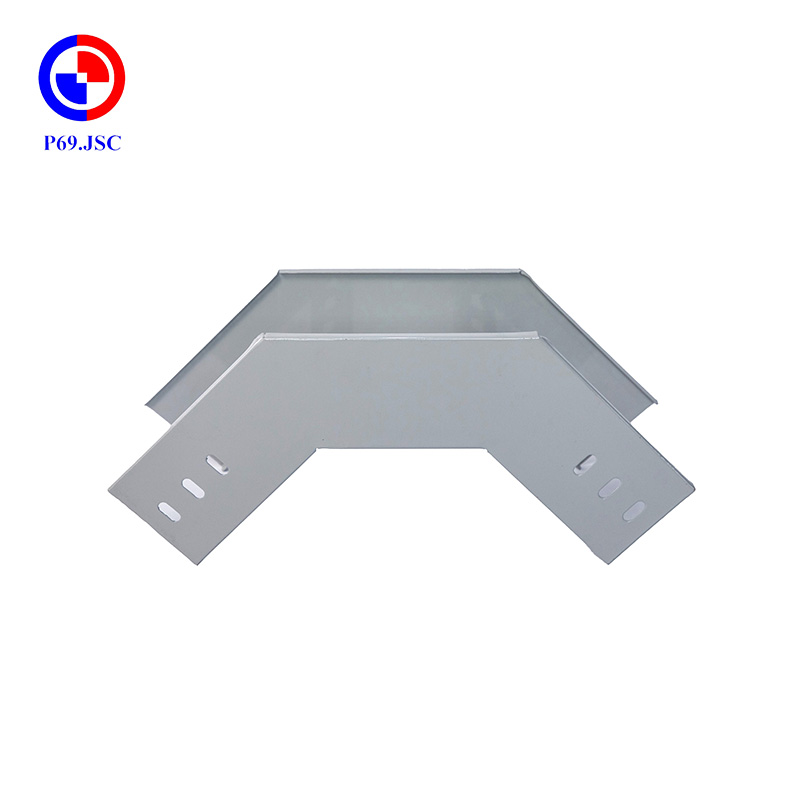

7.2 Co vuông

Phụ kiện co vuông (co 90, co L, co ngang, co góc) đóng vai trò quan trọng trong việc biến đổi hướng đi của thang cáp. Phụ kiện này có khả năng chuyển đổi hệ thống thang đang tiến thẳng thành một góc 90 độ, tạo điểm quay hoặc biến đổi hướng mà không cần sử dụng các phụ kiện khác.

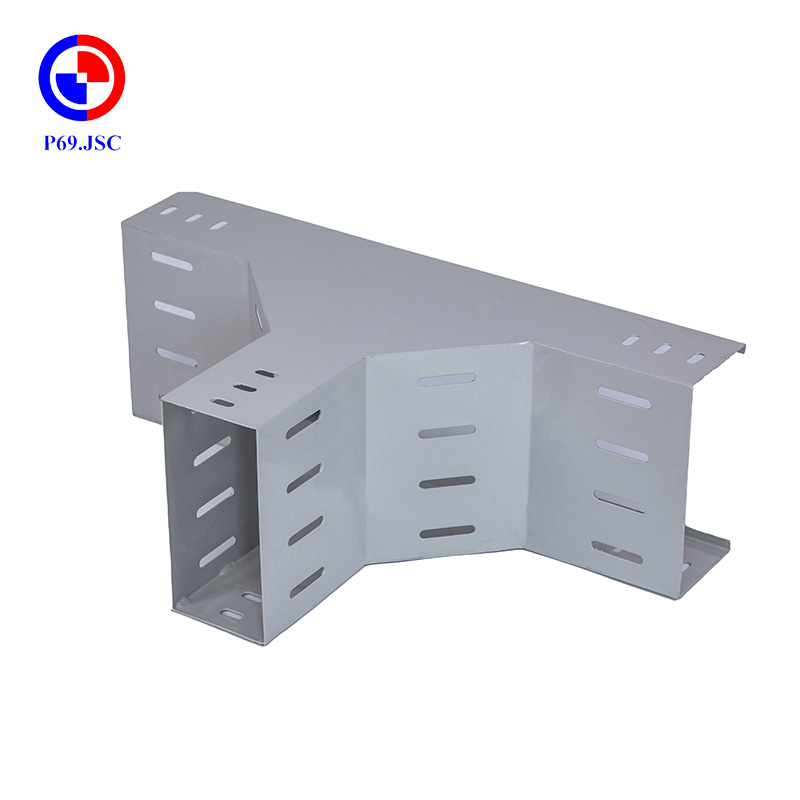

7.3. Tê thang cáp

Tê là một phụ kiện được sử dụng để rẽ nhanh đường đây cáp thành 2 hướng khác nhau trong hệ thống thang. Khi đường dây phụ cần rẽ nhánh mà vẫn muốn giữ nguyên được hướng đi và vị trí của đường dây chính thì đơn vị thi công sẽ sử dụng tê để hướng đường dây phụ sang hướng khác.

7.4 Co xuống và co lên

Co lên và co xuống được sử dụng tại những vị trí cần thay đổi góc độ của đường dây cáp. Về bản chất, hai loại phụ kiện này có hình thù và đặc điểm giống nhau nhưng cách gọi khác nhau do cách sử dụng. Co xuống được sử dụng để hướng đường dây cáp đi xuống còn con lên được sử dụng để hướng đường dây cáp đi lên.

7.5 Côn lệch và côn đều

Đây là hai loại phụ kiện có cấu tạo khác nhau nhưng lại chung một công dụng đó là co hẹp độ rộng của đường dây cáp. Côn lệch thì đầu côn sẽ được lệch về bên tay phải hoặc tay trái tùy thuộc vào thiết kế của đường dây còn côn đều thì sẽ có đầu côn co đều vào giữa. Tùy thuộc vào sự thay đổi của hệ thống dây cáp mà các đầu co sẽ có kích thước tùy chỉnh theo thiết kế.

7.9 Bulong

Bulong thường được sử dụng để liên kết và gắn cố định các đoạn thang cáp lại với nhau, tạo ra một hệ thống thang hoàn chỉnh. Bulong được làm từ các loại vật liệu chất lượng cao, như thép không gỉ hoặc thép mạ kẽm, để đảm bảo sự bền bỉ và độ an toàn của hệ thống. Khi sử dụng bulong, bạn có thể kiểm soát độ căng của nó để đảm bảo rằng hệ thống thang hoạt động ổn định.

8. Giá thành của thang cáp phụ thuộc vào yếu tố nào?

Kích thước của thang cáp đóng vai trò quan trọng trong việc xác định giá thành. Sản phẩm có thể có nhiều kích thước khác nhau để phù hợp với từng công trình riêng biệt. Khi kích thước càng lớn, cần sử dụng nhiều vật liệu hơn và nhân công thì dẫn đến giá thành cao hơn.

Ngoài ra, độ dày của tôn dùng để làm thang cũng ảnh hưởng đến giá thành. Loại tôn có độ dày khác nhau sẽ có giá khác nhau. Những loại tôn có độ bền lớn và có khả năng chịu tải nặng thường đòi hỏi tôn dày hơn, làm tăng giá thành của sản phẩm.

Hơn nữa, lớp sơn mạ bên ngoài không chỉ làm cho sản phẩm trở nên bắt mắt mà còn bảo vệ khỏi sự ăn mòn và oxi hóa. Lớp sơn mạ có hai loại chính là sơn tĩnh điện và mạ kẽm nhúng nóng. Nếu khách hàng lựa chọn các màu sơn khác với màu sơn tiêu chuẩn thì giá thành có thể cao hơn một chút.

Bên cạnh đó, mỗi đơn vị cung cấp sẽ có một mức báo giá khác nhau, vậy nên để xác định giá thành thang cáp điện một cách chính xác và nhanh chóng, bạn nên tham khảo các đơn vị uy tín. Những đơn vị này sẽ tư vấn cụ thể cho bạn về các sản phẩm phù hợp với nhu cầu sử dụng cũng như tính thẩm mỹ cao nhất cho công trình. Sự chuyên nghiệp và kinh nghiệm của đơn vị cung cấp có thể đảm bảo bạn nhận được giá trị tốt nhất cho khoản đầu tư của mình.

9. Nguyên nhân khiến thang cáp mạ kẽm bị han gỉ, ăn mòn?

9.1 Những nguyên nhân khiến thang cáp mạ kẽm bị han gỉ, ăn mòn

Mặc dù thang cáp được mạ kẽm để bảo vệ khỏi ăn mòn, nhưng vẫn có khả năng bị han gỉ và ăn mòn do một số nguyên nhân sau:

Tiếp xúc với nước: Sản phẩm thường được sử dụng trong môi trường ngoài trời hoặc trong các nơi có độ ẩm cao, vậy nên phải tiếp xúc liên tục với nước, trong khi nước là một yếu tố có tính ăn mòn. Nước có khả năng xâm nhập vào lớp mạ kẽm và gây ra sự oxi hóa của kim loại, dẫn đến han gỉ và ăn mòn.

Tiếp xúc với hóa chất: Thang cáp có thể phải đối mặt với nhiều hóa chất trong môi trường làm việc hoặc trong quá trình bảo trì. Các hóa chất mạnh như axit, kiềm hoặc các hóa chất độc hại khác có thể gây ra hủy hoại cho lớp mạ kẽm bên ngoài.

Công trình xây dựng và lắp đặt: Quá trình lắp đặt và xử lý bề mặt thang như cắt, hàn hoặc độn nối không được thực hiện đúng cách có thể gây ra hư hỏng cho lớp mạ kẽm trên bề mặt.

Môi trường ngoài trời khắc nghiệt: Các yếu tố môi trường như tia UV từ mặt trời, gió mạnh, bụi bẩn, mưa và sóng biển đều có thể gây ra hư hỏng lớp mạ kẽm. Môi trường công nghiệp cũng có thể tạo ra các yếu tố độc hại cho sản phẩm.

Tuổi thọ của lớp mạ kẽm: Dù lớp mạ kẽm có độ bền cao, nhưng sau một thời gian dài sử dụng nó cũng có thể bị mòn một cách tự nhiên. Tuổi thọ của lớp mạ kẽm phụ thuộc vào nhiều yếu tố, bao gồm chất lượng của lớp mạ ban đầu, điều kiện môi trường và cách sử dụng sản phẩm.

9.2 Cách bảo quản Thang cáp mạ Kẽm

Bảo quản thang cáp mạ kẽm là một phần quan trọng để đảm bảo độ bền và tính hiệu suất của nó trong thời gian dài. Dưới đây là một số cách để bảo quản sản phẩm:

Bảo vệ khỏi ẩm và nước: Độ ẩm và nước có thể gây oxi hóa và ăn mòn lớp mạ kẽm trên thang cáp. Do đó, cần sử dụng sản phẩm trong môi trường khô ráo, thoáng mát, tránh tiếp xúc với nước.

Tránh va đập và gãy gập: Hạn chế va đập hoặc gãy gập thang. Những va chạm này có thể làm hỏng lớp mạ kẽm và làm giảm khả năng chống ăn mòn của sản phẩm.

Kiểm tra định kỳ: Hãy kiểm tra định kỳ thang mạ kẽm để xác định và xử lý sớm bất kỳ dấu hiệu của ăn mòn, xước hoặc hỏng hóc. Việc này giúp đảm bảo sản phẩm luôn ở trong tình trạng tốt nhất và sẵn sàng sử dụng.

Không sử dụng chất tẩy rửa hoặc hóa chất ăn mòn: Tránh sử dụng chất tẩy rửa hoặc hóa chất ăn mòn trực tiếp lên thang mạ kẽm, vì chúng có thể làm hỏng lớp mạ kẽm và giảm tính kháng ăn mòn của thang. Nếu cần làm sạch, hãy sử dụng nước và xà phòng nhẹ.

Lưu trữ đúng cách: Khi không sử dụng, lưu trữ thang cáp mạ kẽm ở nơi khô ráo, thoáng mát và tránh ánh nắng trực tiếp, sử dụng màng bọc để bảo vệ thang khỏi bụi bẩn và hơi nước.

10 Tại sao nên lắp thang cáp điện?

Thang cáp điện được thiết kế để sắp xếp và quản lý hệ thống đường điện một cách hiệu quả. Việc sử dụng thang cáp giúp giữ cho các dây điện được bố trí gọn gàng và đảm bảo tính nguyên vẹn của chúng. Điều này không chỉ giúp tránh xơ cắt dây điện mà còn làm cho hệ thống trở nên dễ quản lý hơn.

Ngoài ra, thang cáp điện giúp tạo ra một môi trường làm việc an toàn cho nhân viên và hệ thống điện. Nó giúp ngăn chặn tiếp xúc ngẫu nhiên với dây điện, giảm nguy cơ tai nạn và sự cố. Hơn nữa, hệ thống thang cáp điện thường được lắp đặt nhanh chóng và dễ dàng, giúp tiết kiệm thời gian trong quá trình xây dựng hoặc cải tạo nhà máy.

Bên cạnh đó, Thang cáp điện được làm từ các nguyên vật liệu chất lượng cao, giúp nó chịu được môi trường khắc nghiệt và đảm bảo tuổi thọ sử dụng lâu dài. Do đó, sản phẩm thường ít đòi hỏi chi phí bảo trì và sửa chữa, làm giảm tổng chi phí cho dự án.

Trên đây là tất cả những thông tin cần thiết về thang cáp điện mà Nhà Máy Cơ Khí P69 chia sẻ để quý khách có cái nhìn tổng quan hơn trong việc lựa chọn và sử dụng sản phẩm một cách hợp lý. Nếu có điều gì thắc mắc xin đừng ngần ngại nhấc máy liên hệ tới số Hotline 0966.686.969 hoặc 0989.188.982 để được tư vấn đầy đủ và chi tiết nhất.

Video chi tiết về Thang cáp sơn tĩnh điện

3 đánh giá cho THANG CÁP ĐIỆN

Chưa có đánh giá nào.